Studding outlets, or pad flanges, are vital parts used in different industrial setups to connect pipes and vessels. Class 150 studding outlet flanges are specifically designed for applications with a maximum pressure of 150 PSI. In this article, we’ll explore the essential dimensions of these flanges, including their sizes and materials, which can be valuable information for engineering and industrial projects.

Image source: Texasflange

Image source: Texasflange

Understanding Class 150 Flanges

Class 150 studding outlet flanges are categorized based on their pressure rating. The Class 150 label means these flanges can handle a maximum pressure of 150 pounds per square inch (PSI). This classification helps people choose the right components for their systems.

Key Dimensions of Class 150 Studding Outlet Flanges

Image source: Texasflange

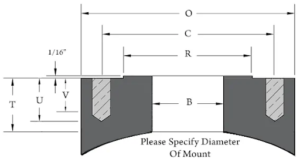

These flanges come in various sizes, designed to meet specific industrial needs. Here are the critical dimensions for Class 150 studding outlet flanges:

- Bore: This is the opening’s diameter in the studding outlet, ranging from 1/2 inch to 24 inches for Class 150 flanges.

- Outer Diameter (OD): The flange’s width, available in different sizes to fit various pipe diameters.

- Thickness: Ensures structural strength and follows ASME standards.

- Outer Diameter of the Raised Face (RF): Important for creating a secure, leak-free connection with another component.

- Stud Circle: The arrangement of bolt holes is crucial for proper installation and stability.

- Hole Diameter: Matches the bolt size for a secure connection.

- Number of Holes: Ensures stability and safety of the connection.

- Hole Depth: Determines the type of bolts or studs used for installation.

- Tap Size and Threads Per Inch (T.P.I.): The size and thread specifications for bolt holes.

- Tap Depth: The depth of the threaded holes for structural integrity.

- Flat Bottom Weight: The weight of the flange, affecting transportation and installation, particularly in larger projects.

Exploring the Benefits

- Versatility: Class 150 studding outlet flanges have various uses in different industries, such as pipe covers and flow control devices in pipelines. Their flexibility makes them valuable in multiple scenarios.

- Customization: Manufacturers can tailor these flanges to project specifications, ensuring they fit perfectly into the application, which enhances performance.

- Quality Assurance: Manufacturers adhere to strict quality standards to maintain customer satisfaction and product quality.

Frequently Asked Questions (FAQs):

What is the significance of Class 150 in studding outlet flanges?

Class 150 indicates the maximum pressure, in pounds per square inch (PSI), that these flanges can handle in industrial applications.

What are the typical bore sizes for Class 150 studding outlet flanges?

Bore sizes range from 1/2 inch to 24 inches for Class 150 flanges.

Why is the outer diameter (OD) of the flange important?

The OD determines the flange’s width and must match the pipe diameter for proper fit.

How does the thickness of Class 150 flanges conform to ASME standards?

The thickness is designed to ensure structural strength and meets ASME standards for safety and reliability.

What is the purpose of the raised face (RF) outer diameter in these flanges?

The RF helps create a secure and leak-free connection when attaching the flange to another component.

Why are the hole arrangement and hole depth essential in studding outlet flanges?

Properly arranged holes and hole depth are crucial for secure installation and the stability of the connection.

What do the tap size and threads per inch (T.P.I.) indicate?

Tap size and T.P.I. specify the size and threading of the bolt holes, ensuring they match the bolts used for installation.

How does the choice of materials impact Class 150 studding outlet flanges?

These flanges are typically made from SA-105 but can also be crafted from stainless steel and various alloys to suit different project requirements.

Can Class 150 studding outlet flanges be customized to fit specific shapes?

Yes, they can be tailored to fit shapes such as shells, heads, or cones, although customization may incur an additional cost.

Are Class 150 studding outlet flanges suitable for both small and large-scale projects?

Yes, these flanges offer versatility and can be used in various applications, making them suitable for projects of different scales.

Do Class 150 studding outlet flanges conform to international standards?

Yes, they follow ANSI and ASME standards to ensure compatibility and reliability in various industrial settings.

What should I consider when choosing between different bore sizes for studding outlet flanges?

The choice of bore size should align with the pipe diameter and the specific requirements of your project.

Are Class 150 studding outlet flanges easy to install?

Installation depends on the project and application. Proper alignment, bolt selection, and torque are essential for successful installation.

How do I determine the ideal thickness for Class 150 studding outlet flanges for my application?

The flange’s thickness should meet ASME standards and be chosen based on the structural requirements and the pressure conditions of your system.

Can these flanges be used for high-temperature applications?

While they can handle pressures up to 150 PSI, the suitability for high-temperature applications may depend on the material used, and this should be analyzed for each specific case.

Conclusion

In summary, understanding the dimensions of Class 150 studding outlet flanges is crucial when selecting components for engineering and industrial projects. These flanges are designed to meet industry standards, available in various sizes and materials, providing versatility for different applications. Whether it’s a small or large-scale project, Class 150 studding outlet flanges can be tailored to your specific requirements, ensuring a secure connection.

For more in-depth information on Studding Outlet Flanges, consider exploring the following resources:

https://www.texasflange.com/products/flange-dims-weights/studding-outlets-for-flanges/

https://www.texasflange.com/blog/a-note-on-studding-outlet-flanges/